high uniformity ultrasonic tšesaane filimi fafatsa barbotage sisteme bakeng sa mafura cell

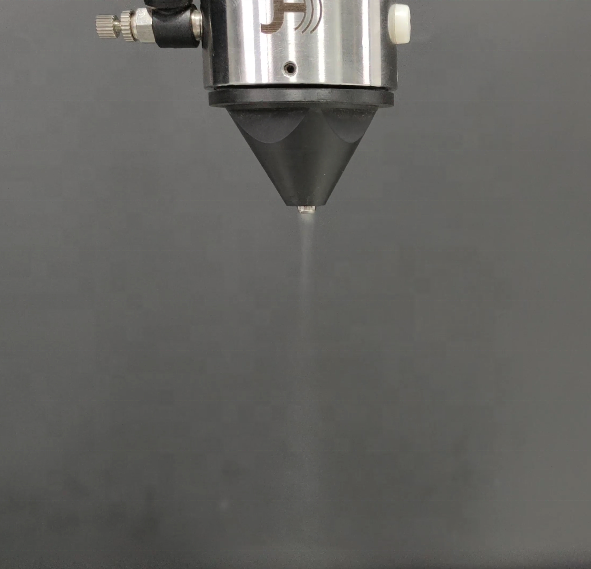

Li-nozzles tsa Ultrasonic li sebetsa ka ho fetola maqhubu a molumo oa maqhubu a phahameng hore e be matla a mochini a fetisetsoang mokelikeli, a etsa maqhubu a emeng. Ha mokelikeli o tsoa ka holim'a atomizing ea molomo, o robeha hore e be moholi o motle oa marotholi a lekanang le micron.

Ho fapana le li-nozzles tsa khatello, li-nozzles tsa ultrasonic ha li qobelle metsi ka har'a sekoti se senyenyane se sebelisa khatello e phahameng e le hore se hlahise spray. Mokelikeli o fepeloa bohareng ba nozzle e nang le sekoti se batlang se le seholo, ntle le khatello, 'me se na le athomo ka lebaka la ho thothomela ha ultrasonic molomong.

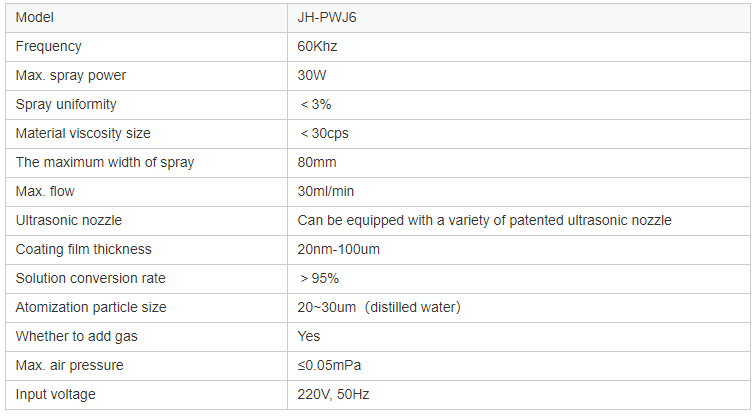

Nozzle e 'ngoe le e' ngoe ea ultrasonic e sebetsa ka nako e itseng ea resonant, e laolang boholo ba marotholi a bohareng. Mohlala, nozzle ea 60 kHz e hlahisa lerotholi le tlase la li-microns tse 20 (ha u fafatsa metsi). Ha sekhahla se phahame, boholo ba marotholi a bohareng bo nyane.

TLHALOSO:

MOLEMO:

* Ho fafatsa ka mokhoa o ts'oanang: ultrasonic e ka etsa likaroloana ho micron kapa esita le boemo ba nanometer, likaroloana tse nyane li netefatsa hore ho na le phello e tšoanang ea ho fafatsa.

* Botenya ba lera bo ka laoloa: ho fafatsa ka ultrasonic ho ka laola ka nepo sekhahla sa phallo, e le ho laola botenya ba lera.

* Ho boloka thepa le ts'ireletso ea tikoloho: ho fafatsa sekhahla sa phallo e tlase ea ultrasonic ho ka fokotsa 80% ea tšebeliso ea lisebelisoa tsa ho fafatsa, basebetsi ha ba hloke ho ikopanya ka kotloloho le lisebelisoa tsa ho fafatsa, ts'ireletso e eketsehileng ea tikoloho.

* Ts'ebetso e phahameng le ho boloka matla: mokelikeli o fetisetsoa hloohong ka matla a khoheli kapa pompo ea khatello e tlase le atomization e tsoelang pele kapa ea nakoana, ha ho na blockage, ha ho na lerata, ha ho lerata, ha ho khatello, ha ho na likarolo tse tsamaeang, ha ho na tlhoko ea metsi a pholileng ka atomization, tšebeliso e nyane ea matla, lisebelisoa tse bonolo, sekhahla se tlase sa ho hloleha, sefafatsi sa ultrasonic se na le ts'ebetso ea ho itlhoekisa le ho itlhokomela.

* Ts'ebetso e phahameng le ho boloka matla: mokelikeli o fetisetsoa hloohong ka matla a khoheli kapa pompo ea khatello e tlase le atomization e tsoelang pele kapa ea nakoana, ha ho na blockage, ha ho na lerata, ha ho lerata, ha ho khatello, ha ho na likarolo tse tsamaeang, ha ho na tlhoko ea metsi a pholileng ka atomization, tšebeliso e nyane ea matla, lisebelisoa tse bonolo, sekhahla se tlase sa ho hloleha, sefafatsi sa ultrasonic se na le ts'ebetso ea ho itlhoekisa le ho itlhokomela.

LIKOPO:

* Lisele tsa mafura

* Lisele tsa photovoltaic tsa filimi e tšesaane

* Liaparo tsa letsatsi tse tšesaane tsa filimi

* Lisele tsa letsatsi tsa Perovskite

* Ho roala ha graphene

* Lisele tsa silicon photovoltaic

* Ho roala ka khalase

* Lipotoloho tsa elektroniki

* Hlooho ea spray e ka sebelisoa ho litharollo tse fapaneng, likhoerekhoere, mokelikeli oa lik'hemik'hale le mucus oa oli le tsona li ka ba atomized.

* Lisele tsa photovoltaic tsa filimi e tšesaane

* Liaparo tsa letsatsi tse tšesaane tsa filimi

* Lisele tsa letsatsi tsa Perovskite

* Ho roala ha graphene

* Lisele tsa silicon photovoltaic

* Ho roala ka khalase

* Lipotoloho tsa elektroniki

* Hlooho ea spray e ka sebelisoa ho litharollo tse fapaneng, likhoerekhoere, mokelikeli oa lik'hemik'hale le mucus oa oli le tsona li ka ba atomized.

Ngola molaetsa wa hao mona mme o re romele wona