ultrasonic biodiesel processor bakeng sa ho kopanya metsi a oli nanoemulsion

Ha o etsa biodiesel, li-kinetics tse liehang ho arabela le ho fetisa boima bo fokolang li fokotsa matla a semela sa biodiesel le lihlahisoa tsa hau tsa biodiesel le boleng. JH ultrasonic reactors e ntlafatsa kinetics ea transesterification haholo. Ka hona, methanol e fokotsehile, 'me ho hlokahala hore ho be le li-catalyst tse fokolang bakeng sa ts'ebetso ea biodiesel. Biodiesel e atisa ho hlahisoa ka li-reactor tsa batch ho sebelisa mocheso le motsoako oa mechine e le ho kenya matla. Ultrasonic cavitational ho kopanya ke mokhoa o atlehang oa mokhoa oa ho finyella ho kopanya hantle khoebong ea biodiesel. Ultrasonic cavitation e fana ka matla a ts'ebetsong a hlokahalang bakeng sa indasteri ea biodiesel transesterification. Ts'ebetso ea Ultrasonic ea biodiesel e kenyelletsa mehato e latelang:

1. Oli ea meroho kapa mafura a liphoofolo a ntse a kopantsoe le methanol (e etsang methyl esters) kapa ethanol (bakeng sa ethyl esters) le sodium kapa potassium methoxide kapa hydroxide.

2.Motsoako oa futhumatsoa, mohlala, mocheso o pakeng tsa 45 le 65degC.

3.Motsoako o futhumetseng o ntse o etsoa sonicated inline bakeng sa metsotsoana e 5 ho isa ho e 30.

4.Glycerin e theoha kapa e arohane ka ho sebelisa li-centrifuges.

5.Biodiesel e fetotsoeng e hlatsuoa ka metsi. Hangata, sonication e etsoa ka khatello e phahameng (1 ho 3bar, khatello ea gauge) ho sebelisa pompo ea phepelo le valve e ka fetohang ea khatello ea morao haufi le sele ea phallo.

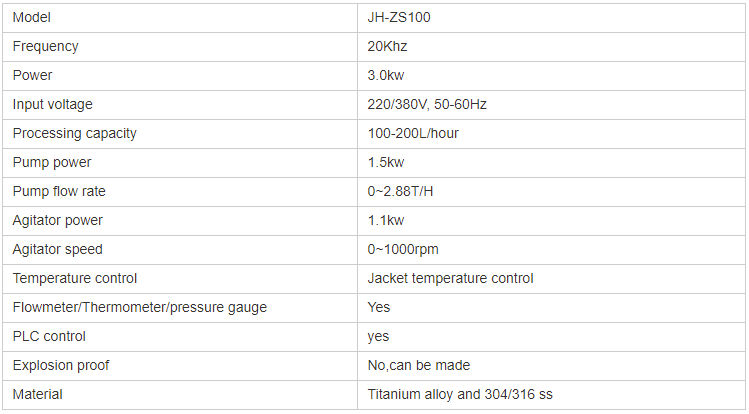

TLHALOSO: