ntlafatso ea lijo-thollo tsa ultrasonic ka li-alloys tsa aluminium

TLHALOSO:

Lisebelisoa tsa ho hloekisa lijo-thollo tsa Ultrasonic'Mesebetsi e ka sehloohong ts'ebetsong ea phekolo ea aluminium e qhibilihisitsoeng ke: ho hloekisa lithollo tsa tšepe, motsoako oa motsoako oa homogenizing, ho ntlafatsa haholo matla le ho hanyetsa mokhathala oa thepa ea ho lahla, ho ntlafatsa thepa e pharaletseng ea thepa, ho fokotsa tšebeliso ea lihlahisoa tsa lijo-thollo le ho fokotsa litšenyehelo.

1. Ho tlosoa ho kenyelletsoa ha Ultrasonic

Ho thata haholo bakeng sa tharollo ea tšepe ho phaphamala ka li-inclusions tse nyane. Ke feela ha ba bokana ba ka phaphamalang. Ha phekolo ea ultrasonic ea tharollo ea aluminium, li-inclusions tse nyenyane li ka behoa le ho kopanngoa. Ka mochini o hloekisang lijo-thollo, likaroloana tse kholo tsa likaroloana li phaphamala ho tlosa litšila.

2. Ultrasonic degassing

ha ho thothomela rekere e kenngoa ka tšepe e qhibilihisitsoeng, ketsahalo ea cavitation e fumanoa, e bakoang ke sekoti se hlahisoang ka mor'a hore ho tsoele pele ha mokelikeli o robehile, kahoo khase e qhibilihisitsoeng ka tšepe ea metsi e lebisa tlhokomelo libakeng tse ling. Ka lebaka la ho sisinyeha ho sisinyehang ha ultrasonic, mokokotlo oa bubble o hlahisoa 'me o ntse o hōla ho fihlela o ka ntšoa ka tšepe e qhibilihisitsoeng.

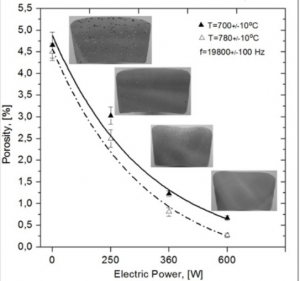

3. Phello ea leqhubu la ultrasonic boleng ba ho lahla embryo

Ha mokhoa oa ho tiisa oa ultrasonic vibration o sebelisoa ho hlahisa li-castings, leqhubu la ultrasonic le tla hlahisa khatello ea molumo o fapaneng oa banner le ho theha jete. Ka lebaka la phello e se nang moeli, basebetsi-'moho le bona ba tla hlahisa phallo ea molumo le micro sound flow, ha puo e se nang letho ea ultrasonic e tla hlahisa jete e phahameng ka potlako ho sebopeho se pakeng tsa se tiileng le sa metsi. Liphello tsena kaofela li ka khaola le ho senya li-dendrites, Kae kapa kae moo ho nang le tšimo ea molumo ka har'a mokelikeli, e bapala karolo. Ho sebelisa phello ea cavitation ts'ebetsong ena, e ka hloekisa sebopeho, ea hloekisa likaroloana le homogenize sebopeho. Ho phaella ho phello ea mochine e bakoang ke ho sisinyeha ho senya li-dendrites, karolo e 'ngoe ea bohlokoa ea ultrasonic vibration solidification ke ho ntlafatsa supercooling e sebetsang ea tšepe ea metsi. Radius ea bohlokoa ea nucleus e fokotsehile. Ka hona, sekhahla sa nucleation sea eketseha 'me lijo-thollo li hloekisoa.

TLHALOSO:

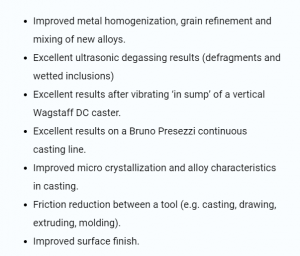

MOLEMO:

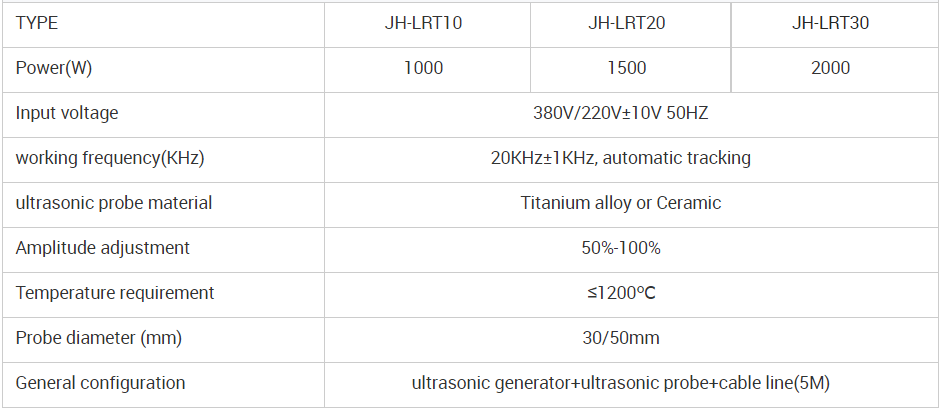

MAEMO: